What is CNC plasma cutter?

CNC plasma cutting machine is a machine for processing metal materials by means of plasma cutting technology. With different gases, it can also cut a variety of metals which is difficult to cut by oxygen cutting , especially for non-ferrous metals (stainless steel, carbon steel, aluminum, copper, titanium, nickel). With the advantages of fast cutting speed, smooth cut surface, little heat distortion and almost no heat affected zone, plasma cutting machines are widely used in automobiles, locomotives, pressure vessels, chemical machinery, nuclear industry, general machinery, engineering machinery, steel structures and other industries!

Model | GC1530P GC1540P GC2040P |

Working area (X-Y) | 1500mmx3000mm 1500*4000mm 2000*4000mm |

Working material | Iron, Steel, Aluminum sheets, Galvanized sheets, Titanium Plates |

Working Thickness | 0.5-40mm |

Cutting Speed | 0-8000mm/min |

Power | 15kw |

Input Voltage | 380V 50HZ (or according to your need) |

Plasma Current | 63A/100A/120A/160A/200A/300A |

Connecting Way | USB |

Working Mode | Untouched arc striking |

Cooling method | With water pump and tank provide circulating water cooling |

Z axis travel | 0-70mm |

The automatic elastic raise | 0-5mm |

Rail guide | Precision work round |

Transmit way | Taiwan imported ball screw |

Operation language | English (Option) |

Command | G code, *uoo, *mmg, *plt |

Optional power source | USA brand Hypertherm powermax 45 65 85 105 125 200 |

Spare parts | Electrode ,Electricity nozzle and Water jacket

|

Features

1. Welded structure of thickening square tube, together with top brand guide rail to ensure high running speed and accuracy.

2. Hypertherm plasma power supply together with high sensitive arc pressure adjuster. Self-adjusting can choose the best distance between plasma gun and working piece automatically to ensure high accuracy cutting.

3. CNC pasma cutter for sheet metal uses STARFIRE control system with FastCAM software for auto material saving function, large capacity storing function, convenient to read and process.

4. Cutting head with cooling system can quickly cool surface of material to avoid burr and residue.

5. Overall stepper motor with high precision rack and pinion, to ensure the cnc plasma cutter has small noise, smooth, precise coordinates of the mobile performance.

6. Perfect software compatibility, such as Ucancam, Type 3, Artcum, etc.

Power Supply

This equipment has high reliability, compact structure, small size, and lightweight. It adopts new technology to reduce the consumption of cutting torch accessories and scientific dust-proof design. Automatic protection function for Undervoltage and phase loss, safety protection has been fully taken into account during design. It is mainly used for plasma cutting of carbon steel, alloy steel, non-ferrous metals, and other metal materials.

Control systerm

High stability control system with user panel for cnc plasma cutting machine, suitable for all kinds of portable flame/plasma cutting machine. The control system is packaged in an all-steel structure cabinet, which can truly prevent electromagnetic radiation, and has excellent anti-interference and anti-static performance.

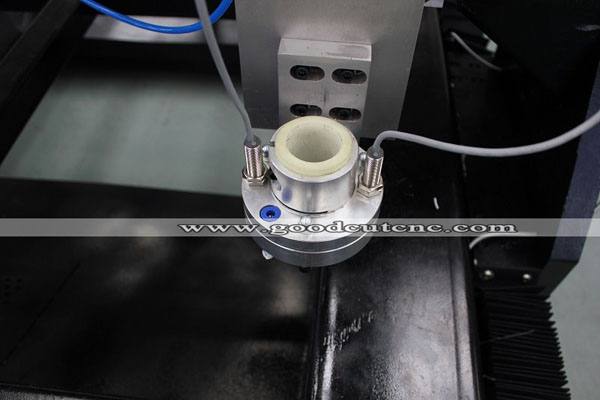

Cutting Torch

The machine plasma torch (cutting torch) has cutting and hole-cutting functions, fast cutting speed, strong cutting ability, high surface quality, smooth cut surface, good durability of consumable parts, reducing production costs and improving production efficiency. Suitable for cutting all kinds of metal materials such as low carbon steel, alloy steel, non-ferrous metals.